PVD-Komponenten

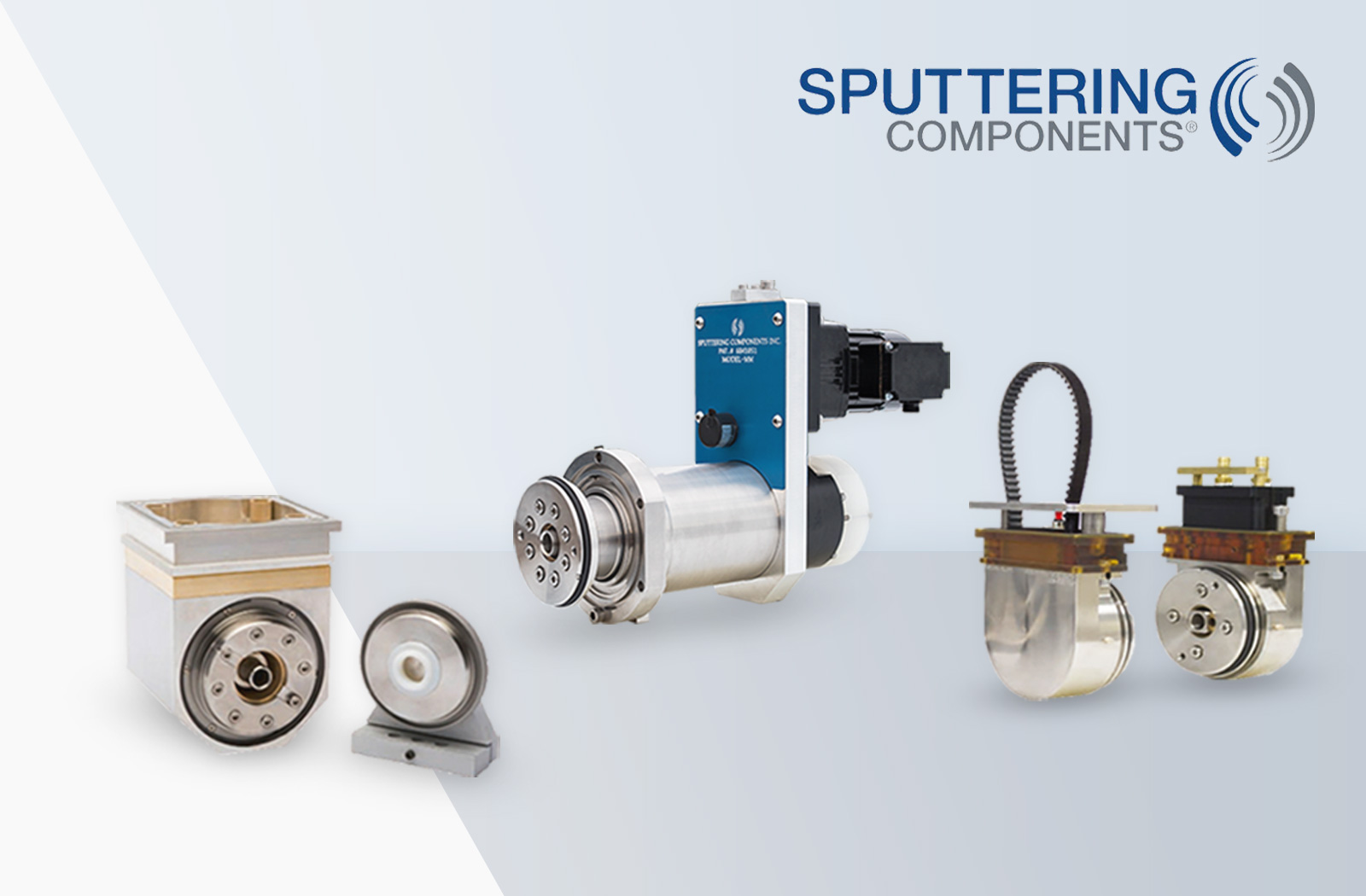

ROHRKATHODEN

Sputtering Components, Inc. ist der weltweit führende Anbieter von zuverlässigen und preiswerten Endblöcken für Rohrkathoden, kompletten Kathodendeckeln und Magnetsystemen nach dem neuesten Stand der Technik. Alle SCI-Produkte ermöglichen dem Endbenutzer schnelle, kostengünstige, hausinterne Wartungsarbeiten. Dies ermöglicht die im Vergleich niedrigsten Gesamtinvestitionskosten.

robeko ist exklusiver Vertriebs- und Servicepartner von Sputtering Components für Mittel- und Osteuropa.

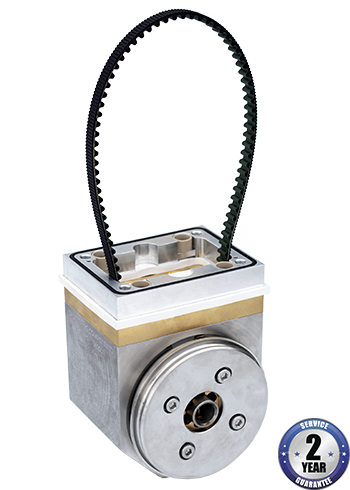

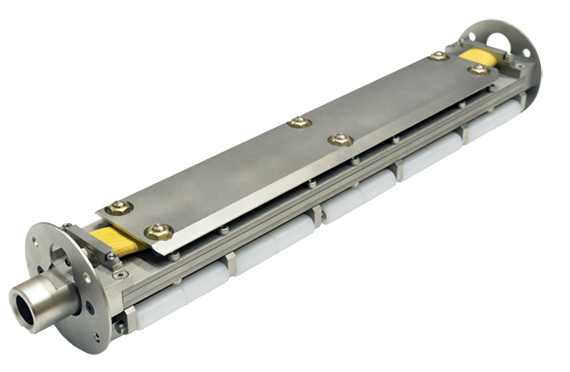

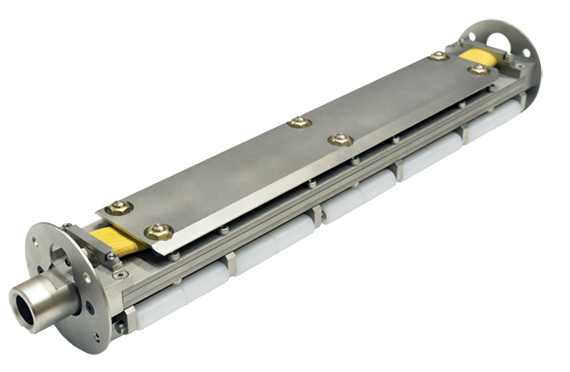

SC-SERIES Internal Mount End Block

The industry-standard size SC-Series, internal mount end block is the lowest cost, highest power, and most reliable end block available.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 40 kg

MC-SERIES Internal Mount End Block

With a more compact design than the SC and a lower power rating, the MC is designed for smaller systems.

Technical Data:

- Power: max. 100 kW DC or MFAC

- V/A: 1500 V/225 A

- Target: max. 2500 mm

- Thickness: 154 mm

- Average weight: 20 kg

cMC-SERIES Internal Mount End Block

The cMC is designed to directly replace compact end blocks from other manufacturers as well as to use in new systems.

Technical Data:

- Power: max. 80 kW DC or MFAC

- V/A: 1500 V/180 A

- Target: max. 2000 mm

- Thickness: 125 mm

CC-SERIES Internal Mount End Block

With its extremely compact package, the CC is designed for 80 mm ID targets, making it an excellent choice for small systems or R&D systems.

Technical Data:

- Power: max. 20 kW DC or MFAC

- V/A: 1500 V/50 A

- Target: max. 1000 mm

- Thickness: 122 mm

TC-SERIES Internal Mount End Block

Designed to replace planar cathodes where space on the end is limited, the TC-Series internal-mount end block will increase the output and quality of your existing coater.

A two-ended design, it has the most compact end block available for standard 125 mm ID industrial targets.

Technical Data:

- Power: max. 40 kW DC or MFAC

- V/A: 1500 V/100 A

- Target: max. 1500 mm

- Thickness: 58 mm on each side

- Average weight: 10 kg

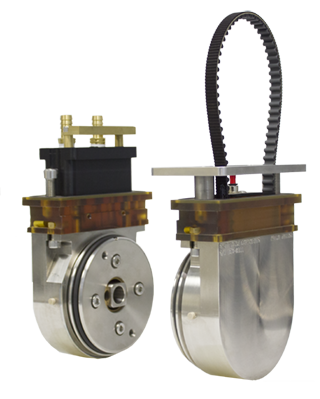

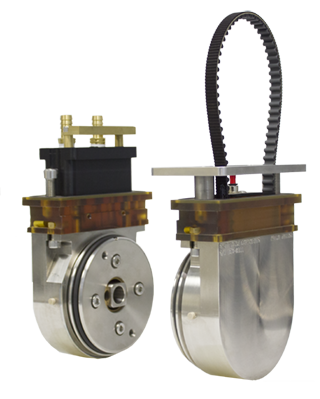

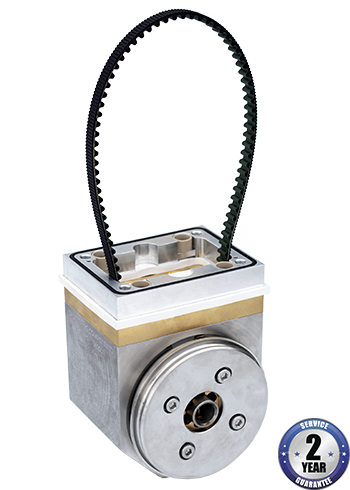

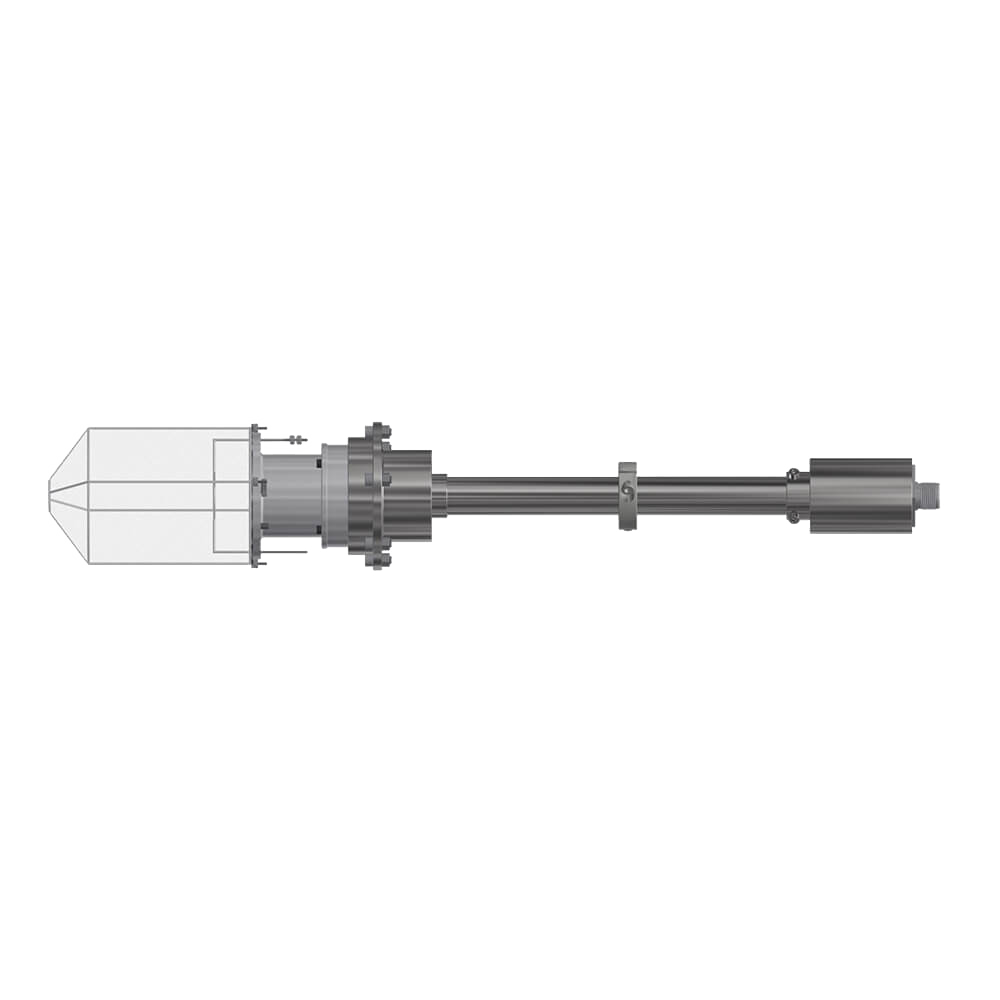

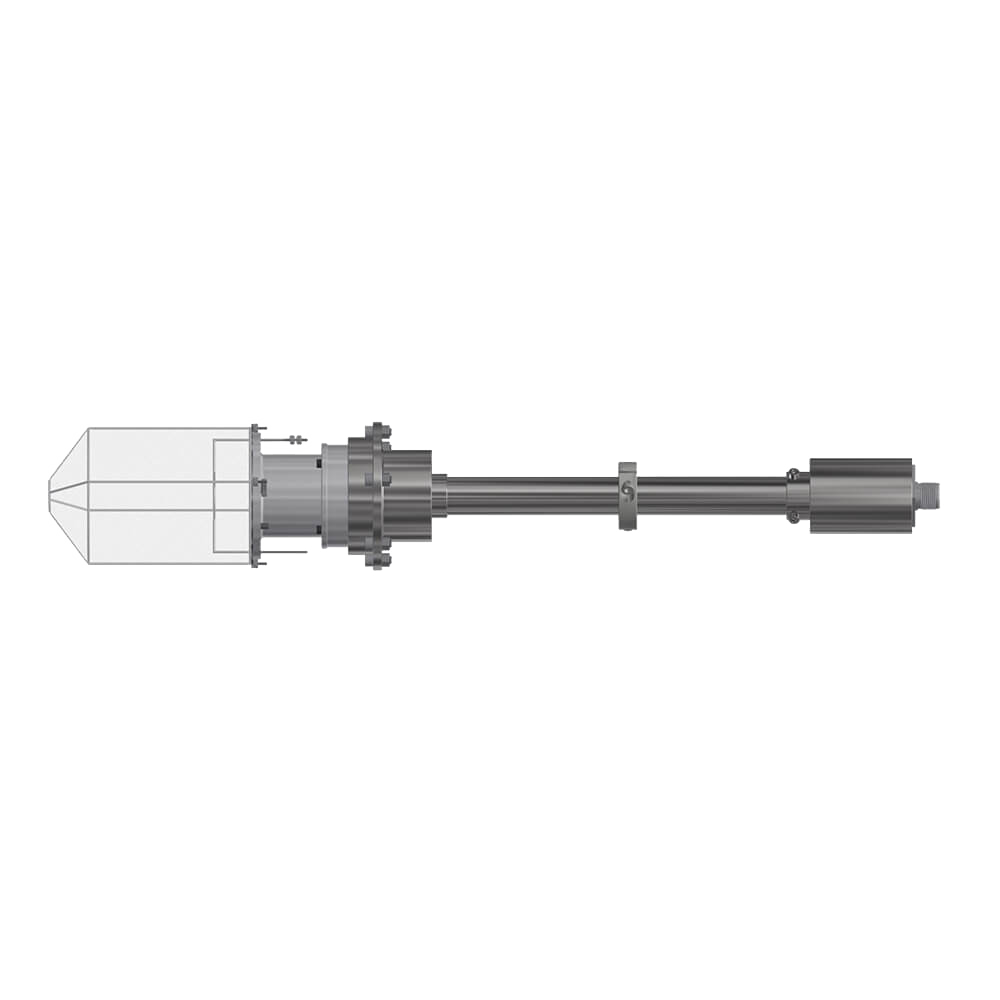

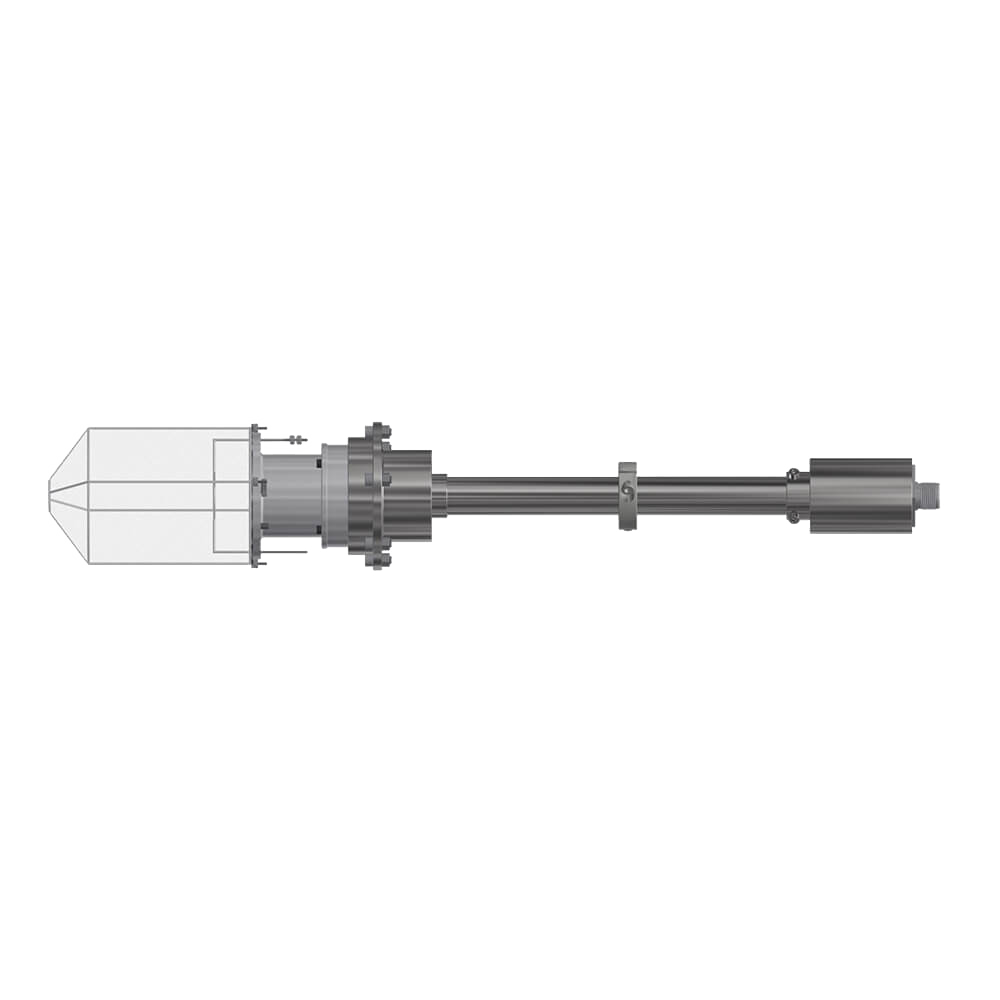

SM-SERIES External Mount End Block

Our largest external-mount end block, the SM can accommodate targets up to 4000 mm (supported) and has a power rating of up to 200 kW DC or 80 kHz MFAC.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and customizable drive shaft length.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 60 kg

MM-SERIES External Mount End Block

The MM is our mid-size external-mount end block.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and a customizable drive shaft length.

Technical Data:

- Power: max. 100 kW DC or MFAC

- V/A: 1500 V/225 A

- Target: max. 2500 mm

- Average weight: 30 kg

CM-SERIES External Mount End Block

For either 125 mm or 80 mm ID diameter targets, the CM is our most compact external-mount end block.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and a customizable drive shaft length.

Technical Data:

- Power: max. 20 kW DC or MFAC

- V/A: 1500 V/50 A

- Target: max. 1000 mm

- Average weight: 15 kg

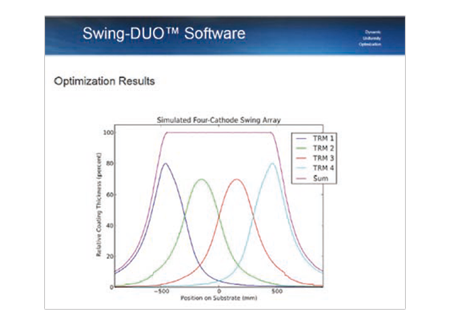

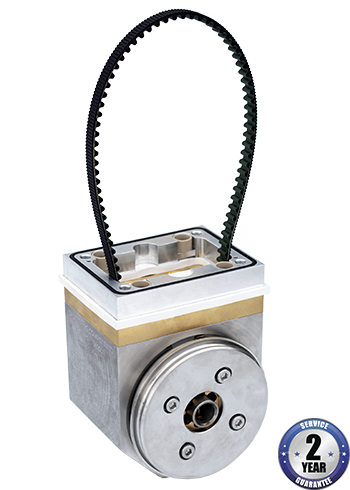

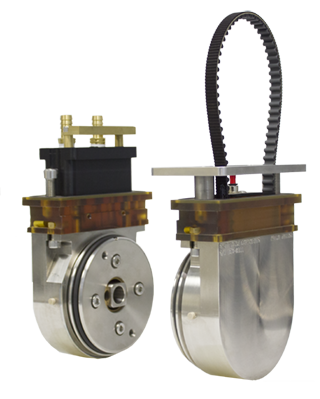

Swing Cathode™ SMS, MMS & CMS

With the Swing Cathode™ external-mount end block, the magnet pack swings in a programmable rotary axis that is independent of the rotating target tube, making it an ideal system for display or 3D part coating.

Other uses for Swing Cathodes™ are to pivot the magnet bar to a burn in location or to make magnet bar position adjustments via remote control.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 15 kg

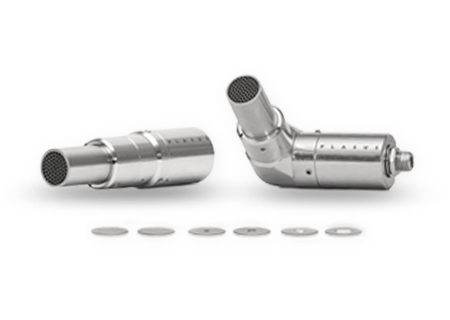

IM End Block

While the typical end block rotates a target tube around a stationary magnet bar, the IM external-mount end block continuously rotates the magnet bar inside a stationary target tube.

- For coating the insides of tubular-shaped objects

- For decorative or tool coatings (where objects are placed around the cathode)

The IM can be configured for targets with inside diameters of either 80 mm or 125 mm.

Technical Data:

- Power: max. 60 kW DC or MFAC

- V/A: 1500 V/150 A

- Target: max. 2000 mm

- Maintenance: Do-it-yourself on your schedule and in your facility; Typical requirements: 1 hr./year to change seals

Magnet Bars for 80 mm ID Targets

Available in two basic models, magnet bars for 80 mm inside diameter targets have the following advantages:

- Designed using 3D finite element analysis software - for meeting your application requirements

- Carefully matched, high-strength magnets that are factory calibrated using an automated magnet bar measurement tool - for uniform coatings

- Fully encapsulated magnets and robust construction - for many years of trouble-free operation

- Long-life, multi-roller system - for reliable sputter up, sputter down or off-angle sputtering

- Magnetic positioning points that are easily set using simple tools - for easy uniformity adjustment

- A simple installation procedure with solutions for vertical installation and connecting to end blocks from other manufacturers

Technical Data:

- Target ID:

TRM/SRM80-Bar™: 115 mm - Gauss (typical):

TRM80-Bar™: To be determined

SRM80-Bar™: 565 - Sputter Angle:

TRM80-Bar™: +/- 19°

SRM80-Bar™: +/- 28°

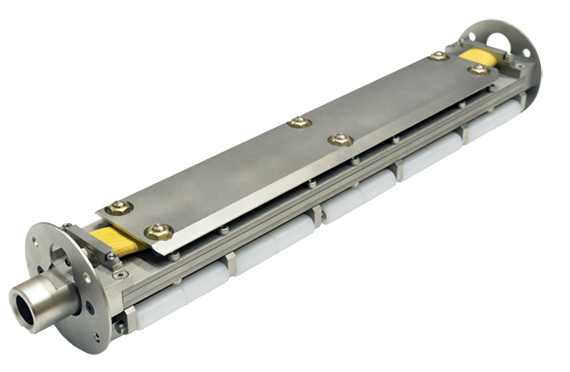

RAM-Bar™

With the Remotely Adjustable Magnet Bar, you can position and fine tune the distance between the magnetics and the target surface from outside the system and during operation to eliminate costly system shutdown.

Compatible with all SCI end blocks for 125 mm ID targets and available with any of the advanced magnetics, the RAM-Bar™ allows for up to 4 mm vertical difference between adjustment locations for very fine tuning. It can attain uniformity requirements of less than +/-1%.

Technical Data:

- Target/Backing Tube Length: max. 550 - 4000 mm

- Maximum Target Diameter: 180 mm

- Adjuster Pitch: 305 mm (12 inches)

- Maximum Film Uniformity: under +/-1%

- Movement Precision: ± 250 µm of travel

ARM-Bar™

We designed the Air Retractable Magnet Bar (ARM-Bar™) for sputtering ferromagnetic materials: alloys of iron, cobalt and a few “rare-earth" elements.

With the magnet bar raised and lowered using air bladders, the ARM-Bar™ provides the utilization and up-time benefits of a rotary cathode while allowing safe and easy insertion into the target, adjustment and removal.

In order to penetrate the magnetic material, the ARM-Bar™ has our strongest magnet bar, the QRM-Bar™.

Typical applications include EMI shielding, nickel sputtering as an adhesion layer for polyimide substrates, and magnetic storage.

e-Cathode™

Sputtering Components e-Cathode™ process lids (compartments) and doors are a turnkey solution for new or existing coaters.

OEM lids for new coaters

Available in both digital and analog formats, vertical or horizontal orientation and customized to end user needs. OEM lids and doors can be purchased as a complete system or scaled-back according to your requirements.

Lid clones

For users needing to add cathodes to their existing coater, our process lid clones match all your current external mechanical and electrical interfaces but use SCI end blocks, magnet bars and control systems. We can also modify your existing lid designs to meet your changing needs.

ROHRKATHODEN

Sputtering Components, Inc. ist der weltweit führende Anbieter von zuverlässigen und preiswerten Endblöcken für Rohrkathoden, kompletten Kathodendeckeln und Magnetsystemen nach dem neuesten Stand der Technik. Alle SCI-Produkte ermöglichen dem Endbenutzer schnelle, kostengünstige, hausinterne Wartungsarbeiten. Dies ermöglicht die im Vergleich niedrigsten Gesamtinvestitionskosten.

robeko ist exklusiver Vertriebs- und Servicepartner von Sputtering Components für Mittel- und Osteuropa.

SC-SERIES Internal Mount End Block

The industry-standard size SC-Series, internal mount end block is the lowest cost, highest power, and most reliable end block available.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 40 kg

MC-SERIES Internal Mount End Block

With a more compact design than the SC and a lower power rating, the MC is designed for smaller systems.

Technical Data:

- Power: max. 100 kW DC or MFAC

- V/A: 1500 V/225 A

- Target: max. 2500 mm

- Thickness: 154 mm

- Average weight: 20 kg

cMC-SERIES Internal Mount End Block

The cMC is designed to directly replace compact end blocks from other manufacturers as well as to use in new systems.

Technical Data:

- Power: max. 80 kW DC or MFAC

- V/A: 1500 V/180 A

- Target: max. 2000 mm

- Thickness: 125 mm

CC-SERIES Internal Mount End Block

With its extremely compact package, the CC is designed for 80 mm ID targets, making it an excellent choice for small systems or R&D systems.

Technical Data:

- Power: max. 20 kW DC or MFAC

- V/A: 1500 V/50 A

- Target: max. 1000 mm

- Thickness: 122 mm

TC-SERIES Internal Mount End Block

Designed to replace planar cathodes where space on the end is limited, the TC-Series internal-mount end block will increase the output and quality of your existing coater.

A two-ended design, it has the most compact end block available for standard 125 mm ID industrial targets.

Technical Data:

- Power: max. 40 kW DC or MFAC

- V/A: 1500 V/100 A

- Target: max. 1500 mm

- Thickness: 58 mm on each side

- Average weight: 10 kg

SM-SERIES External Mount End Block

Our largest external-mount end block, the SM can accommodate targets up to 4000 mm (supported) and has a power rating of up to 200 kW DC or 80 kHz MFAC.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and customizable drive shaft length.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 60 kg

MM-SERIES External Mount End Block

The MM is our mid-size external-mount end block.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and a customizable drive shaft length.

Technical Data:

- Power: max. 100 kW DC or MFAC

- V/A: 1500 V/225 A

- Target: max. 2500 mm

- Average weight: 30 kg

CM-SERIES External Mount End Block

For either 125 mm or 80 mm ID diameter targets, the CM is our most compact external-mount end block.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and a customizable drive shaft length.

Technical Data:

- Power: max. 20 kW DC or MFAC

- V/A: 1500 V/50 A

- Target: max. 1000 mm

- Average weight: 15 kg

Swing Cathode™ SMS, MMS & CMS

With the Swing Cathode™ external-mount end block, the magnet pack swings in a programmable rotary axis that is independent of the rotating target tube, making it an ideal system for display or 3D part coating.

Other uses for Swing Cathodes™ are to pivot the magnet bar to a burn in location or to make magnet bar position adjustments via remote control.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 15 kg

IM End Block

While the typical end block rotates a target tube around a stationary magnet bar, the IM external-mount end block continuously rotates the magnet bar inside a stationary target tube.

- For coating the insides of tubular-shaped objects

- For decorative or tool coatings (where objects are placed around the cathode)

The IM can be configured for targets with inside diameters of either 80 mm or 125 mm.

Technical Data:

- Power: max. 60 kW DC or MFAC

- V/A: 1500 V/150 A

- Target: max. 2000 mm

- Maintenance: Do-it-yourself on your schedule and in your facility; Typical requirements: 1 hr./year to change seals

Magnet Bars for 80 mm ID Targets

Available in two basic models, magnet bars for 80 mm inside diameter targets have the following advantages:

- Designed using 3D finite element analysis software - for meeting your application requirements

- Carefully matched, high-strength magnets that are factory calibrated using an automated magnet bar measurement tool - for uniform coatings

- Fully encapsulated magnets and robust construction - for many years of trouble-free operation

- Long-life, multi-roller system - for reliable sputter up, sputter down or off-angle sputtering

- Magnetic positioning points that are easily set using simple tools - for easy uniformity adjustment

- A simple installation procedure with solutions for vertical installation and connecting to end blocks from other manufacturers

Technical Data:

- Target ID:

TRM/SRM80-Bar™: 115 mm - Gauss (typical):

TRM80-Bar™: To be determined

SRM80-Bar™: 565 - Sputter Angle:

TRM80-Bar™: +/- 19°

SRM80-Bar™: +/- 28°

RAM-Bar™

With the Remotely Adjustable Magnet Bar, you can position and fine tune the distance between the magnetics and the target surface from outside the system and during operation to eliminate costly system shutdown.

Compatible with all SCI end blocks for 125 mm ID targets and available with any of the advanced magnetics, the RAM-Bar™ allows for up to 4 mm vertical difference between adjustment locations for very fine tuning. It can attain uniformity requirements of less than +/-1%.

Technical Data:

- Target/Backing Tube Length: max. 550 - 4000 mm

- Maximum Target Diameter: 180 mm

- Adjuster Pitch: 305 mm (12 inches)

- Maximum Film Uniformity: under +/-1%

- Movement Precision: ± 250 µm of travel

ARM-Bar™

We designed the Air Retractable Magnet Bar (ARM-Bar™) for sputtering ferromagnetic materials: alloys of iron, cobalt and a few “rare-earth" elements.

With the magnet bar raised and lowered using air bladders, the ARM-Bar™ provides the utilization and up-time benefits of a rotary cathode while allowing safe and easy insertion into the target, adjustment and removal.

In order to penetrate the magnetic material, the ARM-Bar™ has our strongest magnet bar, the QRM-Bar™.

Typical applications include EMI shielding, nickel sputtering as an adhesion layer for polyimide substrates, and magnetic storage.

e-Cathode™

Sputtering Components e-Cathode™ process lids (compartments) and doors are a turnkey solution for new or existing coaters.

OEM lids for new coaters

Available in both digital and analog formats, vertical or horizontal orientation and customized to end user needs. OEM lids and doors can be purchased as a complete system or scaled-back according to your requirements.

Lid clones

For users needing to add cathodes to their existing coater, our process lid clones match all your current external mechanical and electrical interfaces but use SCI end blocks, magnet bars and control systems. We can also modify your existing lid designs to meet your changing needs.

ROHRKATHODEN

Sputtering Components, Inc. ist der weltweit führende Anbieter von zuverlässigen und preiswerten Endblöcken für Rohrkathoden, kompletten Kathodendeckeln und Magnetsystemen nach dem neuesten Stand der Technik. Alle SCI-Produkte ermöglichen dem Endbenutzer schnelle, kostengünstige, hausinterne Wartungsarbeiten. Dies ermöglicht die im Vergleich niedrigsten Gesamtinvestitionskosten.

robeko ist exklusiver Vertriebs- und Servicepartner von Sputtering Components für Mittel- und Osteuropa.

SC-SERIES Internal Mount End Block

The industry-standard size SC-Series, internal mount end block is the lowest cost, highest power, and most reliable end block available.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 40 kg

MC-SERIES Internal Mount End Block

With a more compact design than the SC and a lower power rating, the MC is designed for smaller systems.

Technical Data:

- Power: max. 100 kW DC or MFAC

- V/A: 1500 V/225 A

- Target: max. 2500 mm

- Thickness: 154 mm

- Average weight: 20 kg

cMC-SERIES Internal Mount End Block

The cMC is designed to directly replace compact end blocks from other manufacturers as well as to use in new systems.

Technical Data:

- Power: max. 80 kW DC or MFAC

- V/A: 1500 V/180 A

- Target: max. 2000 mm

- Thickness: 125 mm

CC-SERIES Internal Mount End Block

With its extremely compact package, the CC is designed for 80 mm ID targets, making it an excellent choice for small systems or R&D systems.

Technical Data:

- Power: max. 20 kW DC or MFAC

- V/A: 1500 V/50 A

- Target: max. 1000 mm

- Thickness: 122 mm

TC-SERIES Internal Mount End Block

Designed to replace planar cathodes where space on the end is limited, the TC-Series internal-mount end block will increase the output and quality of your existing coater.

A two-ended design, it has the most compact end block available for standard 125 mm ID industrial targets.

Technical Data:

- Power: max. 40 kW DC or MFAC

- V/A: 1500 V/100 A

- Target: max. 1500 mm

- Thickness: 58 mm on each side

- Average weight: 10 kg

SM-SERIES External Mount End Block

Our largest external-mount end block, the SM can accommodate targets up to 4000 mm (supported) and has a power rating of up to 200 kW DC or 80 kHz MFAC.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and customizable drive shaft length.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 60 kg

MM-SERIES External Mount End Block

The MM is our mid-size external-mount end block.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and a customizable drive shaft length.

Technical Data:

- Power: max. 100 kW DC or MFAC

- V/A: 1500 V/225 A

- Target: max. 2500 mm

- Average weight: 30 kg

CM-SERIES External Mount End Block

For either 125 mm or 80 mm ID diameter targets, the CM is our most compact external-mount end block.

It uses the same patented technology as our internal end blocks to deliver outstanding value, performance and reliability but has a wider substrate coverage and a customizable drive shaft length.

Technical Data:

- Power: max. 20 kW DC or MFAC

- V/A: 1500 V/50 A

- Target: max. 1000 mm

- Average weight: 15 kg

Swing Cathode™ SMS, MMS & CMS

With the Swing Cathode™ external-mount end block, the magnet pack swings in a programmable rotary axis that is independent of the rotating target tube, making it an ideal system for display or 3D part coating.

Other uses for Swing Cathodes™ are to pivot the magnet bar to a burn in location or to make magnet bar position adjustments via remote control.

Technical Data:

- Power: max. 200 kW DC or MFAC

- V/A: 1500 V/450 A

- Target: max. 4000 mm

- Average weight: 15 kg

IM End Block

While the typical end block rotates a target tube around a stationary magnet bar, the IM external-mount end block continuously rotates the magnet bar inside a stationary target tube.

- For coating the insides of tubular-shaped objects

- For decorative or tool coatings (where objects are placed around the cathode)

The IM can be configured for targets with inside diameters of either 80 mm or 125 mm.

Technical Data:

- Power: max. 60 kW DC or MFAC

- V/A: 1500 V/150 A

- Target: max. 2000 mm

- Maintenance: Do-it-yourself on your schedule and in your facility; Typical requirements: 1 hr./year to change seals

Magnet Bars for 80 mm ID Targets

Available in two basic models, magnet bars for 80 mm inside diameter targets have the following advantages:

- Designed using 3D finite element analysis software - for meeting your application requirements

- Carefully matched, high-strength magnets that are factory calibrated using an automated magnet bar measurement tool - for uniform coatings

- Fully encapsulated magnets and robust construction - for many years of trouble-free operation

- Long-life, multi-roller system - for reliable sputter up, sputter down or off-angle sputtering

- Magnetic positioning points that are easily set using simple tools - for easy uniformity adjustment

- A simple installation procedure with solutions for vertical installation and connecting to end blocks from other manufacturers

Technical Data:

- Target ID:

TRM/SRM80-Bar™: 115 mm - Gauss (typical):

TRM80-Bar™: To be determined

SRM80-Bar™: 565 - Sputter Angle:

TRM80-Bar™: +/- 19°

SRM80-Bar™: +/- 28°

RAM-Bar™

With the Remotely Adjustable Magnet Bar, you can position and fine tune the distance between the magnetics and the target surface from outside the system and during operation to eliminate costly system shutdown.

Compatible with all SCI end blocks for 125 mm ID targets and available with any of the advanced magnetics, the RAM-Bar™ allows for up to 4 mm vertical difference between adjustment locations for very fine tuning. It can attain uniformity requirements of less than +/-1%.

Technical Data:

- Target/Backing Tube Length: max. 550 - 4000 mm

- Maximum Target Diameter: 180 mm

- Adjuster Pitch: 305 mm (12 inches)

- Maximum Film Uniformity: under +/-1%

- Movement Precision: ± 250 µm of travel

ARM-Bar™

We designed the Air Retractable Magnet Bar (ARM-Bar™) for sputtering ferromagnetic materials: alloys of iron, cobalt and a few “rare-earth" elements.

With the magnet bar raised and lowered using air bladders, the ARM-Bar™ provides the utilization and up-time benefits of a rotary cathode while allowing safe and easy insertion into the target, adjustment and removal.

In order to penetrate the magnetic material, the ARM-Bar™ has our strongest magnet bar, the QRM-Bar™.

Typical applications include EMI shielding, nickel sputtering as an adhesion layer for polyimide substrates, and magnetic storage.

e-Cathode™

Sputtering Components e-Cathode™ process lids (compartments) and doors are a turnkey solution for new or existing coaters.

OEM lids for new coaters

Available in both digital and analog formats, vertical or horizontal orientation and customized to end user needs. OEM lids and doors can be purchased as a complete system or scaled-back according to your requirements.

Lid clones

For users needing to add cathodes to their existing coater, our process lid clones match all your current external mechanical and electrical interfaces but use SCI end blocks, magnet bars and control systems. We can also modify your existing lid designs to meet your changing needs.

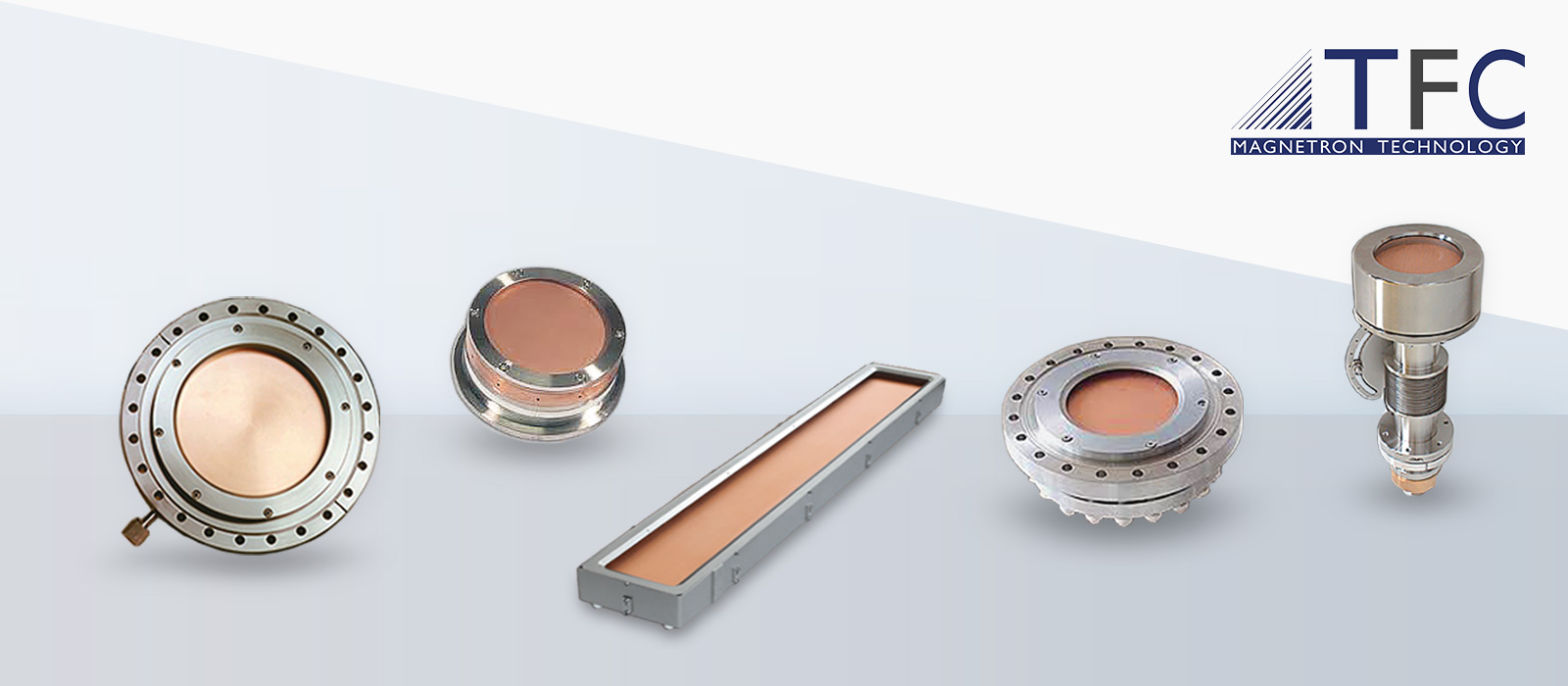

PLANARKATHODEN

Die einzigartigen IONIX Magnetron-Sputterquellen verfügen über eine flexible Architektur, um den teilweise widersprüchlichen Leistungsanforderungen der modernen Vakuumbeschichtungstechnologie gerecht zu werden. Das IONIX-Konzept basiert auf maximaler Zuverlässigkeit, anpassungsfähigem Magnetarray-Layout und vielseitigem Design, um sich an die spezifischen Anwendungen des Kunden anzupassen.

robeko ist seit 2017 Vertriebspartner für Thin Film Consulting – seit 2023 TFC GmbH.

Rectangular Magnetrons

IONIX® rectangular magnetron sputtering sources with advanced water cooling circuits are designed for industrial production purposes, offering:

• High-reate metallic sputtering

• RF sputtering of dielectric targets

• Pulsed reactive mode sputtering for high rate

• Deposition of dielectric thin films

PLANARKATHODEN

Die einzigartigen IONIX Magnetron-Sputterquellen verfügen über eine flexible Architektur, um den teilweise widersprüchlichen Leistungsanforderungen der modernen Vakuumbeschichtungstechnologie gerecht zu werden. Das IONIX-Konzept basiert auf maximaler Zuverlässigkeit, anpassungsfähigem Magnetarray-Layout und vielseitigem Design, um sich an die spezifischen Anwendungen des Kunden anzupassen.

robeko ist seit 2017 Vertriebspartner für Thin Film Consulting – seit 2023 TFC GmbH.

Rectangular Magnetrons

IONIX® rectangular magnetron sputtering sources with advanced water cooling circuits are designed for industrial production purposes, offering:

• High-reate metallic sputtering

• RF sputtering of dielectric targets

• Pulsed reactive mode sputtering for high rate

• Deposition of dielectric thin films

PLANARKATHODEN

Die einzigartigen IONIX Magnetron-Sputterquellen verfügen über eine flexible Architektur, um den teilweise widersprüchlichen Leistungsanforderungen der modernen Vakuumbeschichtungstechnologie gerecht zu werden. Das IONIX-Konzept basiert auf maximaler Zuverlässigkeit, anpassungsfähigem Magnetarray-Layout und vielseitigem Design, um sich an die spezifischen Anwendungen des Kunden anzupassen.

robeko ist seit 2017 Vertriebspartner für Thin Film Consulting – seit 2023 TFC GmbH.

Rectangular Magnetrons

IONIX® rectangular magnetron sputtering sources with advanced water cooling circuits are designed for industrial production purposes, offering:

• High-reate metallic sputtering

• RF sputtering of dielectric targets

• Pulsed reactive mode sputtering for high rate

• Deposition of dielectric thin films

HF-GENERATOREN

robeko bietet Produkte der Seren IPS Inc. an, einem führenden Hersteller von elektrischen Generatoren und Zubehör für die Erzeugung und Einspeisung von HF Leistung für Plasma- und andere Anwendungen.

Seren IPS. Inc. sichert durch kontinuierliche Produktentwicklung in Verbindung mit erstklassigem Applications Engineering den Erfolg unserer Kunden.

Der Vertrieb für Seren IPS Inc. in Europa wird gemeinsam mit der RF-Industrie in Großbritannien durchgeführt.

SEREN Power Supplies

robeko provides products of Seren IPS Inc., a leading manufacturer of RF power delivery components.

At Seren IPS. Inc., innovative technology, applications and design expertise are combined with world class support to deliver critical RF power solutions including RF Generators, Matching Networks and accessories. Continuous product development and dedicated Application/Design Engineering services ensure success for our customers.

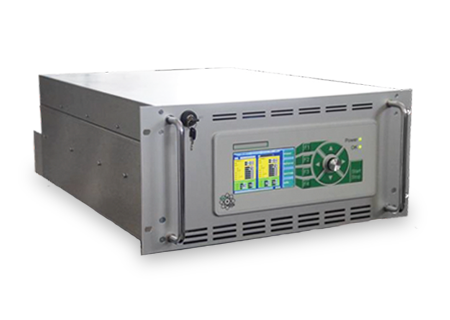

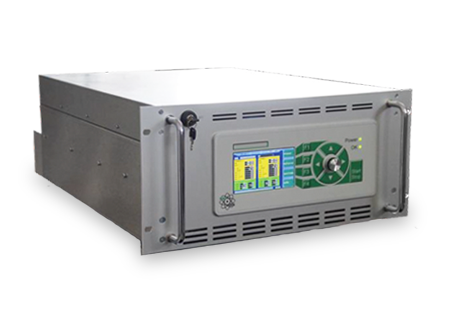

SEREN RF-Generators, R & HR-Series

Seren “HR Series” products incorporate a separate surface mount technology printed circuit board for controls and RF amplifier. The RF amplifier is powered by a switch-mode power supply.

Seren “HR Series” products utilize LDMOS Field-Effect Transistors in the power amplifier stages. The unit operates in a class AB mode providing power accuracy and stability across the entire power range.

HF-GENERATOREN

robeko bietet Produkte der Seren IPS Inc. an, einem führenden Hersteller von elektrischen Generatoren und Zubehör für die Erzeugung und Einspeisung von HF Leistung für Plasma- und andere Anwendungen.

Seren IPS. Inc. sichert durch kontinuierliche Produktentwicklung in Verbindung mit erstklassigem Applications Engineering den Erfolg unserer Kunden.

Der Vertrieb für Seren IPS Inc. in Europa wird gemeinsam mit der RF-Industrie in Großbritannien durchgeführt.

SEREN Power Supplies

robeko provides products of Seren IPS Inc., a leading manufacturer of RF power delivery components.

At Seren IPS. Inc., innovative technology, applications and design expertise are combined with world class support to deliver critical RF power solutions including RF Generators, Matching Networks and accessories. Continuous product development and dedicated Application/Design Engineering services ensure success for our customers.

SEREN RF-Generators, R & HR-Series

Seren “HR Series” products incorporate a separate surface mount technology printed circuit board for controls and RF amplifier. The RF amplifier is powered by a switch-mode power supply.

Seren “HR Series” products utilize LDMOS Field-Effect Transistors in the power amplifier stages. The unit operates in a class AB mode providing power accuracy and stability across the entire power range.

HF-GENERATOREN

robeko bietet Produkte der Seren IPS Inc. an, einem führenden Hersteller von elektrischen Generatoren und Zubehör für die Erzeugung und Einspeisung von HF Leistung für Plasma- und andere Anwendungen.

Seren IPS. Inc. sichert durch kontinuierliche Produktentwicklung in Verbindung mit erstklassigem Applications Engineering den Erfolg unserer Kunden.

Der Vertrieb für Seren IPS Inc. in Europa wird gemeinsam mit der RF-Industrie in Großbritannien durchgeführt.

SEREN Power Supplies

robeko provides products of Seren IPS Inc., a leading manufacturer of RF power delivery components.

At Seren IPS. Inc., innovative technology, applications and design expertise are combined with world class support to deliver critical RF power solutions including RF Generators, Matching Networks and accessories. Continuous product development and dedicated Application/Design Engineering services ensure success for our customers.

SEREN RF-Generators, R & HR-Series

Seren “HR Series” products incorporate a separate surface mount technology printed circuit board for controls and RF amplifier. The RF amplifier is powered by a switch-mode power supply.

Seren “HR Series” products utilize LDMOS Field-Effect Transistors in the power amplifier stages. The unit operates in a class AB mode providing power accuracy and stability across the entire power range.

PULS GENERATOREN

Die Puls Generatoren von Ionautics und Magpuls bieten höchste Flexibilität und höchste Leistung für Plasmanitrierungsprozesse, Vorspannungsanwendungen und Magnetron-Sputtern, einschließlich ambitionierter reaktiver und HIPIMS-Prozesse.

HiPSTER 1 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER BiPolar 1 HiPIMS Pulser

Our HiPSTER BiPolar HiPIMS units belong to a new generation of HiPIMS technology. They are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER BiPolar is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER BiPolar can be connected either to two existing DC power supplies (positive and negative output) or to our tailor-made HiPSTER DC units.

HiPSTER 6 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER BiPolar 6 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER 10 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool whendeveloping and running state-of-the-art HiPIMS processes. HiPSTER 10 is a 10 kW HiPIMS unit for industrial use and R&D departments and suitable for magnetron sizes up to 800 cm2.

HiPSTER Sync Unit

The HiPSTER synchronization unit allows the user to control the pulsing of up to eight HiPSTER HiPIMS powersupplies, compatible HiPSTER bias units, or compatible diagnostic hardware. This enables, for example, pulse trains synchronized between multiple units, or synchronized and delayed pulses. For increased flexibility, the HiPSTER synchronization unit can be triggered externally.

HiPNano

Our nanoparticle cluster source is designed by experts in the field with long experience in nanoparticle production for different applications. With its quick installation using

standard tube feedthroughs and easily interchangeable target cathodes, this nanoparticle source is optimized for high vacuum systems where an additional source for nanoparticles is desired. HiPNano is operated in high-power pulsed mode and optimized for our HiPSTER 1 HiPIMS unit.

MAGPULS Pulse Units

Magpuls Pulse Power supplies provide highest flexibility and supreme performance for plasma nitriting processes, bias applications and magnetron sputtering including ambitious reactive and HIPIMS processes.

The MAGPULS Unipolar and Bipolar Pulse Power Supply series MP 1, MP 2 and MP 2 – HC are constructed in two separate units. One unit is the DC power supply which provides the DC power into the big capacitor bank of the pulse unit and the pulse unit with the integrated sophisticated ARC Management.

MP 1 - Unipolar Pulse Unit

The unipolar pulsed Power Supplies are designed in modular technology. The main components of these power supplies are the DC-Power supply and the pulsing unit which generate the pulsed output voltage with adjustable pulse frequency in the range from DC up to 100kHz. The Arc-management with highest efficiency is adjustable for all different Plasma treatment processes and grants a proper layer quality without any layer damages on the surface.

MP 2 - Bipolar Pulse Unit

The bipolar pulsed power supplies model MAGPULS BP are constructed for plasma excitation with highest performance. The bipolar pulsed power supply is a modular designed system consisting of the DC power unit and the bipolar pulse unit, which switches the voltage with a freely adjustable pulse of alternating polarity into the plasma system.

MP 2 - AS Asymmetric Bipolar Pulse Unit

The MAGPULS Bipolar Pulse Power supplies series MP 2 -AS are designed for operating with dual magnetrons for reactive sputtering on substrates as for glass, plastics and metal. The individual operating modes and the enhanced ARC-management allows the bipolar pulse power supplies operation in high quality processes. Typical applications are production of flat panel displays, solar cells, decorative and hard coatings.

MP 2 - HC Bipolar HIPIMS Pulse Unit

Thanks to the short extremely high peak current pulses the pulse power supplies model MAGPULS HPP generate plasma intensity with highest density which leads to an excellent coating quality in high-pulse sputtering (HIPIMS).

Excellent film properties in terms of wear resistance, adhesive strength, hardness and homogeneity.

Easy integration in existing magnetron sputter systems.

PULS GENERATOREN

Die Puls Generatoren von Ionautics und Magpuls bieten höchste Flexibilität und höchste Leistung für Plasmanitrierungsprozesse, Vorspannungsanwendungen und Magnetron-Sputtern, einschließlich ambitionierter reaktiver und HIPIMS-Prozesse.

HiPSTER 1 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER BiPolar 1 HiPIMS Pulser

Our HiPSTER BiPolar HiPIMS units belong to a new generation of HiPIMS technology. They are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER BiPolar is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER BiPolar can be connected either to two existing DC power supplies (positive and negative output) or to our tailor-made HiPSTER DC units.

HiPSTER 6 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER BiPolar 6 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER 10 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool whendeveloping and running state-of-the-art HiPIMS processes. HiPSTER 10 is a 10 kW HiPIMS unit for industrial use and R&D departments and suitable for magnetron sizes up to 800 cm2.

HiPSTER Sync Unit

The HiPSTER synchronization unit allows the user to control the pulsing of up to eight HiPSTER HiPIMS powersupplies, compatible HiPSTER bias units, or compatible diagnostic hardware. This enables, for example, pulse trains synchronized between multiple units, or synchronized and delayed pulses. For increased flexibility, the HiPSTER synchronization unit can be triggered externally.

HiPNano

Our nanoparticle cluster source is designed by experts in the field with long experience in nanoparticle production for different applications. With its quick installation using

standard tube feedthroughs and easily interchangeable target cathodes, this nanoparticle source is optimized for high vacuum systems where an additional source for nanoparticles is desired. HiPNano is operated in high-power pulsed mode and optimized for our HiPSTER 1 HiPIMS unit.

MAGPULS Pulse Units

Magpuls Pulse Power supplies provide highest flexibility and supreme performance for plasma nitriting processes, bias applications and magnetron sputtering including ambitious reactive and HIPIMS processes.

The MAGPULS Unipolar and Bipolar Pulse Power Supply series MP 1, MP 2 and MP 2 – HC are constructed in two separate units. One unit is the DC power supply which provides the DC power into the big capacitor bank of the pulse unit and the pulse unit with the integrated sophisticated ARC Management.

MP 1 - Unipolar Pulse Unit

The unipolar pulsed Power Supplies are designed in modular technology. The main components of these power supplies are the DC-Power supply and the pulsing unit which generate the pulsed output voltage with adjustable pulse frequency in the range from DC up to 100kHz. The Arc-management with highest efficiency is adjustable for all different Plasma treatment processes and grants a proper layer quality without any layer damages on the surface.

MP 2 - Bipolar Pulse Unit

The bipolar pulsed power supplies model MAGPULS BP are constructed for plasma excitation with highest performance. The bipolar pulsed power supply is a modular designed system consisting of the DC power unit and the bipolar pulse unit, which switches the voltage with a freely adjustable pulse of alternating polarity into the plasma system.

MP 2 - AS Asymmetric Bipolar Pulse Unit

The MAGPULS Bipolar Pulse Power supplies series MP 2 -AS are designed for operating with dual magnetrons for reactive sputtering on substrates as for glass, plastics and metal. The individual operating modes and the enhanced ARC-management allows the bipolar pulse power supplies operation in high quality processes. Typical applications are production of flat panel displays, solar cells, decorative and hard coatings.

MP 2 - HC Bipolar HIPIMS Pulse Unit

Thanks to the short extremely high peak current pulses the pulse power supplies model MAGPULS HPP generate plasma intensity with highest density which leads to an excellent coating quality in high-pulse sputtering (HIPIMS).

Excellent film properties in terms of wear resistance, adhesive strength, hardness and homogeneity.

Easy integration in existing magnetron sputter systems.

PULS

GENERATOREN

GENERATOREN

Die Puls Generatoren von Ionautics und Magpuls bieten höchste Flexibilität und höchste Leistung für Plasmanitrierungsprozesse, Vorspannungsanwendungen und Magnetron-Sputtern, einschließlich ambitionierter reaktiver und HIPIMS-Prozesse.

HiPSTER 1 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER BiPolar 1 HiPIMS Pulser

Our HiPSTER BiPolar HiPIMS units belong to a new generation of HiPIMS technology. They are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER BiPolar is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER BiPolar can be connected either to two existing DC power supplies (positive and negative output) or to our tailor-made HiPSTER DC units.

HiPSTER 6 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER BiPolar 6 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool when developing and running state-of-the-art HiPIMS processes. Also, upgrading your existing magnetron system to HiPIMS has never been easier. The HiPSTER can be directly connected either to an existing DC supply or to one of our tailor-made HiPSTER DC units.

HiPSTER 10 HiPIMS Pulser

Our HiPSTER HiPIMS units are designed by experts in the field with an excellent track record of plasma process development and thin film deposition in order to generate robust and repeatable HiPIMS processes.

With the new ultra-fast switching technology and extended HiPIMS pulse control the HiPSTER is a perfect tool whendeveloping and running state-of-the-art HiPIMS processes. HiPSTER 10 is a 10 kW HiPIMS unit for industrial use and R&D departments and suitable for magnetron sizes up to 800 cm2.

HiPSTER Sync Unit

The HiPSTER synchronization unit allows the user to control the pulsing of up to eight HiPSTER HiPIMS powersupplies, compatible HiPSTER bias units, or compatible diagnostic hardware. This enables, for example, pulse trains synchronized between multiple units, or synchronized and delayed pulses. For increased flexibility, the HiPSTER synchronization unit can be triggered externally.

HiPNano

Our nanoparticle cluster source is designed by experts in the field with long experience in nanoparticle production for different applications. With its quick installation using

standard tube feedthroughs and easily interchangeable target cathodes, this nanoparticle source is optimized for high vacuum systems where an additional source for nanoparticles is desired. HiPNano is operated in high-power pulsed mode and optimized for our HiPSTER 1 HiPIMS unit.

MAGPULS Pulse Units

Magpuls Pulse Power supplies provide highest flexibility and supreme performance for plasma nitriting processes, bias applications and magnetron sputtering including ambitious reactive and HIPIMS processes.

The MAGPULS Unipolar and Bipolar Pulse Power Supply series MP 1, MP 2 and MP 2 – HC are constructed in two separate units. One unit is the DC power supply which provides the DC power into the big capacitor bank of the pulse unit and the pulse unit with the integrated sophisticated ARC Management.

MP 1 - Unipolar Pulse Unit

The unipolar pulsed Power Supplies are designed in modular technology. The main components of these power supplies are the DC-Power supply and the pulsing unit which generate the pulsed output voltage with adjustable pulse frequency in the range from DC up to 100kHz. The Arc-management with highest efficiency is adjustable for all different Plasma treatment processes and grants a proper layer quality without any layer damages on the surface.

MP 2 - Bipolar Pulse Unit

The bipolar pulsed power supplies model MAGPULS BP are constructed for plasma excitation with highest performance. The bipolar pulsed power supply is a modular designed system consisting of the DC power unit and the bipolar pulse unit, which switches the voltage with a freely adjustable pulse of alternating polarity into the plasma system.

MP 2 - AS Asymmetric Bipolar Pulse Unit

The MAGPULS Bipolar Pulse Power supplies series MP 2 -AS are designed for operating with dual magnetrons for reactive sputtering on substrates as for glass, plastics and metal. The individual operating modes and the enhanced ARC-management allows the bipolar pulse power supplies operation in high quality processes. Typical applications are production of flat panel displays, solar cells, decorative and hard coatings.

MP 2 - HC Bipolar HIPIMS Pulse Unit

Thanks to the short extremely high peak current pulses the pulse power supplies model MAGPULS HPP generate plasma intensity with highest density which leads to an excellent coating quality in high-pulse sputtering (HIPIMS).

Excellent film properties in terms of wear resistance, adhesive strength, hardness and homogeneity.

Easy integration in existing magnetron sputter systems.

PLASMA MONITORING &

PROCESS CONTROL

PROCESS CONTROL

Die Prozesssteuerung ist bei industriellen Plasmaanwendungen unerlässlich, um Zuverlässigkeit und hohe Qualität zu gewährleisten. Das EMICON-System ist ein Plasmamonitorsystem, das auf der optischen Emissionsspektroskopie basiert und in Echtzeit gestattet, die Prozesse in Ihrer Plasmaanwendung zu analysieren, zu optimieren und zu steuern.

![]()

EMICON MC | Plasma Monitor and Process Control System

The EMICON MC systems are qualified for most applications in plasma technology for analyzing the plasma, for optimizing the process, for plasma monitoring, for quality control and for process controlling. The turn-key EMICON MC systems come with all features necessary for monitoring common plasma processes and for communicating via analog and digital outputs with the application control.

![]()

EMICON SA | Plasma Monitor and Process Control System

The EMICON SA systems are especially designed for process control and quality assurance in industrial plants and production lines. The integrated processor unit ensures stand-alone operation in 24/7 mode and easy integration of the EMICON SA system into the system conrol by e.g. LAN or Profibus.

![]()

EMICON HR | Plasma Monitor and Process Control System

The EMICON HR system is a high-resolution spectrometer system and it is especially qualified for detailed spectral plasma analysis and plasma monitoring but also for quality control and process controlling. The single channel EMICON HR system comes with all features necessary for monitoring and anaylzing process plasmas in detail.

PLASMA MONITORING &

PROCESS CONTROL

PROCESS CONTROL

Die Prozesssteuerung ist bei industriellen Plasmaanwendungen unerlässlich, um Zuverlässigkeit und hohe Qualität zu gewährleisten. Das EMICON-System ist ein Plasmamonitorsystem, das auf der optischen Emissionsspektroskopie basiert und in Echtzeit gestattet, die Prozesse in Ihrer Plasmaanwendung zu analysieren, zu optimieren und zu steuern.

![]()

EMICON MC | Plasma Monitor and Process Control System

The EMICON MC systems are qualified for most applications in plasma technology for analyzing the plasma, for optimizing the process, for plasma monitoring, for quality control and for process controlling. The turn-key EMICON MC systems come with all features necessary for monitoring common plasma processes and for communicating via analog and digital outputs with the application control.

![]()

EMICON SA | Plasma Monitor and Process Control System

The EMICON SA systems are especially designed for process control and quality assurance in industrial plants and production lines. The integrated processor unit ensures stand-alone operation in 24/7 mode and easy integration of the EMICON SA system into the system conrol by e.g. LAN or Profibus.

![]()

EMICON HR | Plasma Monitor and Process Control System

The EMICON HR system is a high-resolution spectrometer system and it is especially qualified for detailed spectral plasma analysis and plasma monitoring but also for quality control and process controlling. The single channel EMICON HR system comes with all features necessary for monitoring and anaylzing process plasmas in detail.

PLASMA MONITORING &

PROCESS CONTROL

PROCESS CONTROL

Die Prozesssteuerung ist bei industriellen Plasmaanwendungen unerlässlich, um Zuverlässigkeit und hohe Qualität zu gewährleisten. Das EMICON-System ist ein Plasmamonitorsystem, das auf der optischen Emissionsspektroskopie basiert und in Echtzeit gestattet, die Prozesse in Ihrer Plasmaanwendung zu analysieren, zu optimieren und zu steuern.

![]()

EMICON MC | Plasma Monitor and Process Control System

The EMICON MC systems are qualified for most applications in plasma technology for analyzing the plasma, for optimizing the process, for plasma monitoring, for quality control and for process controlling. The turn-key EMICON MC systems come with all features necessary for monitoring common plasma processes and for communicating via analog and digital outputs with the application control.

![]()

EMICON SA | Plasma Monitor and Process Control System

The EMICON SA systems are especially designed for process control and quality assurance in industrial plants and production lines. The integrated processor unit ensures stand-alone operation in 24/7 mode and easy integration of the EMICON SA system into the system conrol by e.g. LAN or Profibus.

![]()

EMICON HR | Plasma Monitor and Process Control System

The EMICON HR system is a high-resolution spectrometer system and it is especially qualified for detailed spectral plasma analysis and plasma monitoring but also for quality control and process controlling. The single channel EMICON HR system comes with all features necessary for monitoring and anaylzing process plasmas in detail.

![]()