PLASMA TREATMENT Components for PVD & PECVD Processes

PLASMA & IONEN BEAM SOURCES

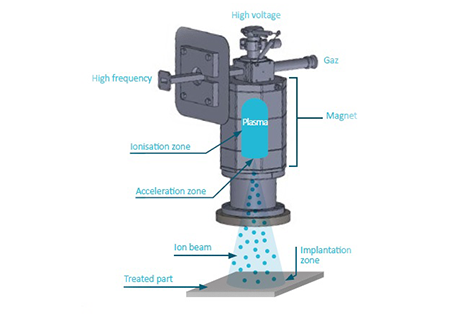

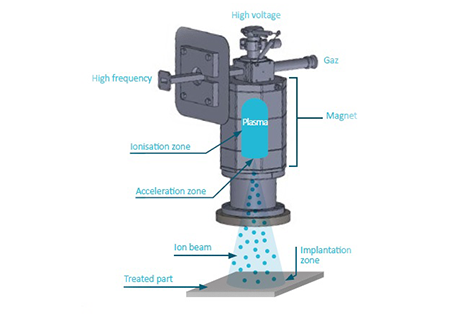

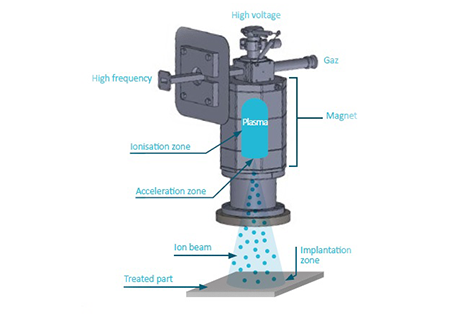

The plasmas required for the treatment and modification of surfaces differ to some extent in their properties from those used in PECVD. The generation is usually based on the same principles as RF or microwave ECR. In order to achieve the exact effect on the surface, the ions in the plasma are often post-accelerated in order to introduce higher energies into the surfaces, or, on the contrary, they are kept away from the substrate in order to avoid damage.

IONICS | ionR2RTM

The ionR2RTMvacuum system is dedicated to the treatment of connectors coils by ion beam implantation. The ion beam implantation process enhances the surface properties (including corrosion resistance, hardness, friction coefficient, optical properties) of precious metal coatings like gold, which decreases the required amount of gold by 4 folds, leading to significant savings on electroplated connectors.

A continuous air to air, reel to reel cost effective process is achieved thanks to an innovative airlock system. Two ion sources (ionGUNTM) ensure a homogeneous and simultaneous treatment on both sides of the connectors strips.

IONICS | ionLAB

IONICS has developed the HARDION industrial ion gun solution solving different technical and economic issues generally associated to the process. Enhance the surface properties of your material without any coatings and using an environmentally friendly technology. The innovation is supported by a Walloon initiative called WALIBEAM and several industrial majors in the fields of surface treatment of glass, metal and polymer are involved.

IONICS | PLAMECOTM

IONICS has developed with MATERIA NOVA’s engineers an innovative low-pressure plasma coating process to treat powders and loose parts. R&D and industrial systems are available equipped with evaporating sources, magnetron or hollow cathodes and even our Hardion ion implantation technologies. Fine tune your system for your application!

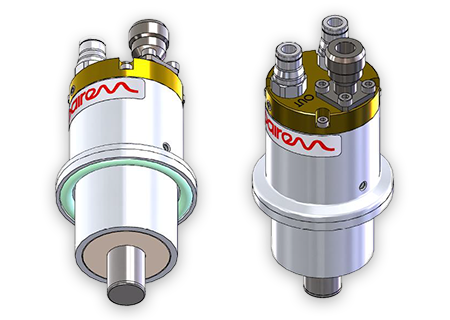

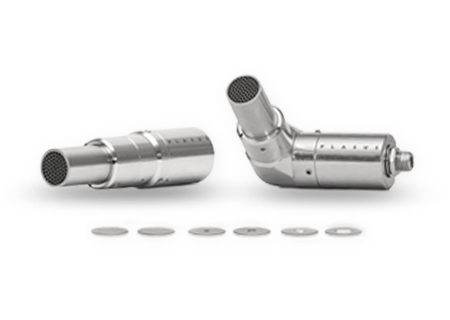

IONICS | ionGUNTM

Since 2017, IONICS has developed a range of low-pressure micro accelerators (ionGUNTM) allowing an efficient and cost-effective use of the ion beam implantation process. An ECR (Electron Cyclotron Resonance) with a dense plasma source produces a multi charged ion beam of up to 10 mA accelerated by an electric field at 35 keV towards the material surface to be treated. Various gases, pure or mixed, are used to enhance surface performances of metal, glasses, ceramics, and polymers. The ion depth penetration depends on the gas, material composition and temperature, initial beam energy and glancing angle. Such ion implantation process enhances surface performances and brings new properties to your material without any added coatings.

envis-Ion™ DMPTS | Dual Magnetron Pretreatment Source

Our largest external-mount end block, the SM can accommodate targets up to 4000 mm (supported) and has a power rating of up to 200 kW DC or 80 kHz MFAC.

The envis-ION™ Dual Magnetron Pretreatment Source has a wide range of operation for improved adhesion and durability.

Technical Data:

• Max Power: 5 KW/m

• Typical Power: 2-4 KW/m

• Operating Pressure: 1-40 m Torr

• Pet Surface Energy at 6.7 m/min: > 65 Dynes

PLASMA & IONEN BEAM SOURCES

The plasmas required for the treatment and modification of surfaces differ to some extent in their properties from those used in PECVD. The generation is usually based on the same principles as RF or microwave ECR. In order to achieve the exact effect on the surface, the ions in the plasma are often post-accelerated in order to introduce higher energies into the surfaces, or, on the contrary, they are kept away from the substrate in order to avoid damage.

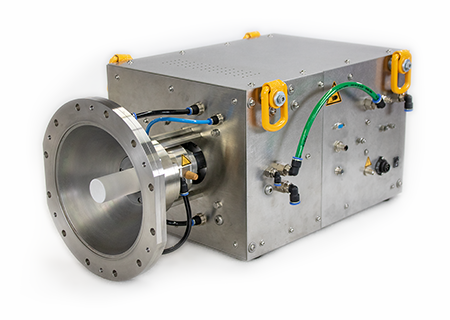

IONICS | ionR2RTM

The ionR2RTMvacuum system is dedicated to the treatment of connectors coils by ion beam implantation. The ion beam implantation process enhances the surface properties (including corrosion resistance, hardness, friction coefficient, optical properties) of precious metal coatings like gold, which decreases the required amount of gold by 4 folds, leading to significant savings on electroplated connectors.

A continuous air to air, reel to reel cost effective process is achieved thanks to an innovative airlock system. Two ion sources (ionGUNTM) ensure a homogeneous and simultaneous treatment on both sides of the connectors strips.

IONICS | IonLAB

IONICS has developed the HARDION industrial ion gun solution solving different technical and economic issues generally associated to the process. Enhance the surface properties of your material without any coatings and using an environmentally friendly technology. The innovation is supported by a Walloon initiative called WALIBEAM and several industrial majors in the fields of surface treatment of glass, metal and polymer are involved.

IONICS | PLAMECOTM

IONICS has developed with MATERIA NOVA’s engineers an innovative low-pressure plasma coating process to treat powders and loose parts. R&D and industrial systems are available equipped with evaporating sources, magnetron or hollow cathodes and even our Hardion ion implantation technologies. Fine tune your system for your application!

IONICS | ionGUNTM

Since 2017, IONICS has developed a range of low-pressure micro accelerators (ionGUNTM) allowing an efficient and cost-effective use of the ion beam implantation process. An ECR (Electron Cyclotron Resonance) with a dense plasma source produces a multi charged ion beam of up to 10 mA accelerated by an electric field at 35 keV towards the material surface to be treated. Various gases, pure or mixed, are used to enhance surface performances of metal, glasses, ceramics, and polymers. The ion depth penetration depends on the gas, material composition and temperature, initial beam energy and glancing angle. Such ion implantation process enhances surface performances and brings new properties to your material without any added coatings.

envis-Ion™ DMPTS | Dual Magnetron Pretreatment Source

Our largest external-mount end block, the SM can accommodate targets up to 4000 mm (supported) and has a power rating of up to 200 kW DC or 80 kHz MFAC.

The envis-ION™ Dual Magnetron Pretreatment Source has a wide range of operation for improved adhesion and durability.

Technical Data:

• Max Power: 5 KW/m

• Typical Power: 2-4 KW/m

• Operating Pressure: 1-40 m Torr

• Pet Surface Energy at 6.7 m/min: > 65 Dynes

PLASMA &

IONEN BEAM

SOURCES

IONEN BEAM

SOURCES

The plasmas required for the treatment and modification of surfaces differ to some extent in their properties from those used in PECVD. The generation is usually based on the same principles as RF or microwave ECR. In order to achieve the exact effect on the surface, the ions in the plasma are often post-accelerated in order to introduce higher energies into the surfaces, or, on the contrary, they are kept away from the substrate in order to avoid damage.

IONICS | ionR2RTM

The ionR2RTMvacuum system is dedicated to the treatment of connectors coils by ion beam implantation. The ion beam implantation process enhances the surface properties (including corrosion resistance, hardness, friction coefficient, optical properties) of precious metal coatings like gold, which decreases the required amount of gold by 4 folds, leading to significant savings on electroplated connectors.

A continuous air to air, reel to reel cost effective process is achieved thanks to an innovative airlock system. Two ion sources (ionGUNTM) ensure a homogeneous and simultaneous treatment on both sides of the connectors strips.

IONICS | IonLAB

IONICS has developed the HARDION industrial ion gun solution solving different technical and economic issues generally associated to the process. Enhance the surface properties of your material without any coatings and using an environmentally friendly technology. The innovation is supported by a Walloon initiative called WALIBEAM and several industrial majors in the fields of surface treatment of glass, metal and polymer are involved.

IONICS | PLAMECOTM

IONICS has developed with MATERIA NOVA’s engineers an innovative low-pressure plasma coating process to treat powders and loose parts. R&D and industrial systems are available equipped with evaporating sources, magnetron or hollow cathodes and even our Hardion ion implantation technologies. Fine tune your system for your application!

IONICS | ionGUNTM

Since 2017, IONICS has developed a range of low-pressure micro accelerators (ionGUNTM) allowing an efficient and cost-effective use of the ion beam implantation process. An ECR (Electron Cyclotron Resonance) with a dense plasma source produces a multi charged ion beam of up to 10 mA accelerated by an electric field at 35 keV towards the material surface to be treated. Various gases, pure or mixed, are used to enhance surface performances of metal, glasses, ceramics, and polymers. The ion depth penetration depends on the gas, material composition and temperature, initial beam energy and glancing angle. Such ion implantation process enhances surface performances and brings new properties to your material without any added coatings.

envis-Ion™ DMPTS | Dual Magnetron Pretreatment Source

Our largest external-mount end block, the SM can accommodate targets up to 4000 mm (supported) and has a power rating of up to 200 kW DC or 80 kHz MFAC.

The envis-ION™ Dual Magnetron Pretreatment Source has a wide range of operation for improved adhesion and durability.

Technical Data:

• Max Power: 5 KW/m

• Typical Power: 2-4 KW/m

• Operating Pressure: 1-40 m Torr

• Pet Surface Energy at 6.7 m/min: > 65 Dynes

PLASMA MONITORING &

PROCESS CONTROL

PROCESS CONTROL

Process control is essential in industrial plasma applications to ensure reliability and high quality. The EMICON system is a plasma monitoring system based on optical emission spectroscopy that allows real-time analysis, optimization and control of the processes in your plasma application.

![]()

EMICON MC | Plasma Monitor and Process Control System

The EMICON MC systems are qualified for most applications in plasma technology for analyzing the plasma, for optimizing the process, for plasma monitoring, for quality control and for process controlling. The turn-key EMICON MC systems come with all features necessary for monitoring common plasma processes and for communicating via analog and digital outputs with the application control.

![]()

EMICON SA | Plasma Monitor and Process Control System

The EMICON SA systems are especially designed for process control and quality assurance in industrial plants and production lines. The integrated processor unit ensures stand-alone operation in 24/7 mode and easy integration of the EMICON SA system into the system conrol by e.g. LAN or Profibus.

![]()

EMICON HR | Plasma Monitor and Process Control System

The EMICON HR system is a high-resolution spectrometer system and it is especially qualified for detailed spectral plasma analysis and plasma monitoring but also for quality control and process controlling. The single channel EMICON HR system comes with all features necessary for monitoring and anaylzing process plasmas in detail.

PLASMA MONITORING &

PROCESS CONTROL

PROCESS CONTROL

Process control is essential in industrial plasma applications to ensure reliability and high quality. The EMICON system is a plasma monitoring system based on optical emission spectroscopy that allows real-time analysis, optimization and control of the processes in your plasma application.

![]()

EMICON MC | Plasma Monitor and Process Control System

The EMICON MC systems are qualified for most applications in plasma technology for analyzing the plasma, for optimizing the process, for plasma monitoring, for quality control and for process controlling. The turn-key EMICON MC systems come with all features necessary for monitoring common plasma processes and for communicating via analog and digital outputs with the application control.

![]()

EMICON SA | Plasma Monitor and Process Control System

The EMICON SA systems are especially designed for process control and quality assurance in industrial plants and production lines. The integrated processor unit ensures stand-alone operation in 24/7 mode and easy integration of the EMICON SA system into the system conrol by e.g. LAN or Profibus.

![]()

EMICON HR | Plasma Monitor and Process Control System

The EMICON HR system is a high-resolution spectrometer system and it is especially qualified for detailed spectral plasma analysis and plasma monitoring but also for quality control and process controlling. The single channel EMICON HR system comes with all features necessary for monitoring and anaylzing process plasmas in detail.

PLASMA MONITORING &

PROCESS CONTROL

PROCESS CONTROL

Process control is essential in industrial plasma applications to ensure reliability and high quality. The EMICON system is a plasma monitoring system based on optical emission spectroscopy that allows real-time analysis, optimization and control of the processes in your plasma application.

![]()

EMICON MC | Plasma Monitor and Process Control System

The EMICON MC systems are qualified for most applications in plasma technology for analyzing the plasma, for optimizing the process, for plasma monitoring, for quality control and for process controlling. The turn-key EMICON MC systems come with all features necessary for monitoring common plasma processes and for communicating via analog and digital outputs with the application control.

![]()

EMICON SA | Plasma Monitor and Process Control System

The EMICON SA systems are especially designed for process control and quality assurance in industrial plants and production lines. The integrated processor unit ensures stand-alone operation in 24/7 mode and easy integration of the EMICON SA system into the system conrol by e.g. LAN or Profibus.

![]()

EMICON HR | Plasma Monitor and Process Control System

The EMICON HR system is a high-resolution spectrometer system and it is especially qualified for detailed spectral plasma analysis and plasma monitoring but also for quality control and process controlling. The single channel EMICON HR system comes with all features necessary for monitoring and anaylzing process plasmas in detail.